Billet Timing Pointer

So I am getting ready to take the Cobra motor to the dyno and I just was not happy with the timing pointer. The billet pointer that goes in the regular spot on the right side of the motor is just difficult to see at best because it is covered up by the water pump. Since timing is so critical I decided to make another pointer that goes on the left of the engine which is completely wide open. This will make the job much easier for Joe who is doing the dyno setup for me. Not to mention it will save some money because at $100 an hour I don't want him hunting around and fighting to get the timing right. I just cut this out of a piece of aluminum angle and cut it to a point. After some filing and some polishing it looks pretty good. There already was a boss on the timing chain cover, all I had to do was drill and tap it. Always something to do right up to the last minute.

Posted by Pete's Hot Rod Garage 0 comments

Labels: Billet Aluminum, timing point

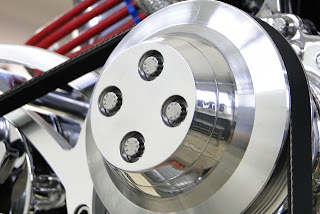

Billet Pulley Cover

Most of the projects I do take a ton of time because I make many custom parts. It's not that I can't use off-the-shelf parts, it's that I have a vision of how I want the finished project to look and that requires custom parts. When building the motor for my Cobra I ran into a problem with water pump selection. I needed a special pulley for the balancer, and the matching pulley for the water pump is usually used for an engine with a fan on it. Since there is no fan on this motor I had a pulley with 8 holes in it and I only needed 4. That left 4 extra holes and an unfinished look. I had some 1/2" 6061 in the shop so I chucked it up in the Tormach personal CNC and wrote a program to drill and countersink the 4 bolt holes. Then the diameter was cut with an end mill. This part was bolted to the water pump pulley and chucked up in the lathe. Working slowly and using a carbide cutter I snuck up on the angle and cut it to size. The final fit was done by hand with emery paper because the profile is not perfectly flat, it has a contour that I followed out to the front. The entire cover was hand wet-sanded and polished. The March pulley came clear powder coated so I sanded down the first angle and polished it to match the cover. The two different finishes follow the style of the rest of the motor where I have polished aluminum and clear powder coated parts. It took just over 3 hours to make this cover and as you can see it finished off the front of that pulley very nice. Including the custom manifold, plated hardware, fabricated air cleaner bottom, powder coating, billet clamps, and polished brass fittings the whole motor took about 6 months to finish. Sure, I was working on other things at the same time, but perfection takes time, and I will stop at nothing to make sure every detail is perfect for the project.OK....my friend Dennis at Wrazen Machining did most of the machining, but I would rather put my work in the hands of another perfectionist. I think you'll agree the work was worth it.

Posted by Pete's Hot Rod Garage 0 comments

Labels: Aluminum Polishing, Billet Aluminum, March Pulley, Pulley Cover

Subscribe to:

Posts (Atom)